Fuel Polishing

The fact that Wind Dragon has been sitting at dock for most likley 1 to 2 years the diesel fuel in the tank needs to be polished. Fuel polishing is the process of filtering out water and trash from the fuel.

One would think, the fuel is in a sealed tank how can water and trash get in? Well it seems that diesel fuel can easily become contaminated with microorganisms such as bacteria, fungi, yeast, mold, and to a lesser extent algae. Diesel fuel in the presence of water and nutrients makes conditions ripe for high bacterial growth. In classical microbiology, microbes will generally need water (H2O), Carbon (C) source, nitrogen (N), phosphorus (P), sulfur (S), trace minerals, and some form of oxygen (free or bound to other atoms) to grow. Most of these conditions are met in fuel tanks and fuel lines. Water and microbes can be introduced from the outside air or other environments. Water can also form from changes in storage temperatures, which causes condensation to occur.

The fact that sailboats generally use very little fuel the water/trash problem tends to be a constant issue. Most diesel fuel tanks end up with quite a bit of crud floating around in the bottom and a bio-film of slime on the sides. In rough water, when a running engine may be vital and changing a fuel filter most nightmarish, this stuff gets stirred up and sucked into the fuel system. Maximum RPM dropping off is the first sign and the engine can be barely running in minutes.

Learning about all this I decided that Wind Dragon should have a system in place to combat this nightmare situation. Now you can purchase fuel polishing systems at a marine supply place that is self contained and ready to go. Sounds great until you see the price tag, $1,000 to over $3,000 OUCH! No way thats going to happen.

Thanks to the google gods though, there is quite a lot of information out there that other poor, mechanicly enclinded people who like to share/brag about what they have done. A good write-up I found was posted by Mr. Long Click here. I also found some ideas from the Bio-Diesel people that saved a lot of money.

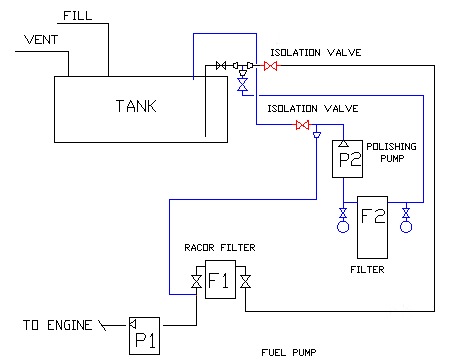

I settled on this system:

P2 will be a Walbro FRA-1-1 Fuel Pump

Walbro FRA-Series Fuel Pumps are the perfect choice where low cost and good durability are important. The FRA-1 fuel pump supersedes the Walbro 2401-1 fuel pump, which has been discontinued. The FRA-1 is one of two pumps that supersede the Walbro 2108-1 fuel pump. (The FRD-1 is also an acceptable replacement for the Walbro 2108-1 fuel pump.)

F2 will be a Plastic (polypropylene) 10″ home water filtration housing with a standard 5 micron water filter (details below)

I will have a vacuum gauge between the filter and pump to keep an eye on the filter as if collects junk. The higher the vacuum the more junk has been collected.

There is also two valves (shown in red on the diagram) that can direct the clean fuel to the engine instead of the tank in case the main (F1) filter gets clogged up.

Filter Details:

This is a water removing filter designed for use in a whole house water filter that uses a 10″ filter cartridge.(available on eBay or most home improvement stores) The inner filter is a standard 5 micron polypropylene filter cartridge and is replaceable. The outer layer is a filter that incorporates a Super-absorbent Polymer that will absorb up to 60 times its volume in water and the impurities carried by water. This filter will not absorb vegetable oils, animal fats or petroleum oils. After the oil exits the inner filter, it is directed through the Super-absorbent Polymer layer which absorbs and holds water but allows the oil to pass right through.

All Walbro Marine and Industrial Fuel Pumps Feature:

- Low Current Draw

- Reverse-Polarity Protected up to 60 minutes

- Self-Priming (Dry Lift) of more than 48″ (120 cm)

- Dry Run to Four Hours

- Compatible With All Commercially-Available Pump-Grade Gasoline, Gasohol, Diesel, or Bio-Diesel

- Operating Temperature from -40° to 155° Farenheit (-40° to 70° Celcius)

- Protection from Transient Voltages to 100 vdc

- US Coast Gard Approved (USCG 16623-1 and USCG 16623-2)

- European CE Standard Approved (EN 61000-6-2 and EN 63-2100)

Additionally, all Walbro FRA-Series Pumps Feature:

- Continuous Duty Life Over 5,000 Hours (Diesel Fuel)

- Weight of 1.63 lbs (0.74 Kg)

- Pump Cycles Continuously When Powered

FRA-1 Pump Specifications:

| Voltage: | 12vdc |

| Minimum Flow: | 20 gph |

| Deadhead Pressure: | 4.5 to 7.0 psi |

| Max Current Draw: | 2.0 amps |

| Life: | >5000 Hours |

| Dry Lift: | 24″ |

| Inlet/Outlet: | 1/8-27 NPSF |

| Electrical Connector | Two leads, no connector |

| Inlet Filter Screen: | NA |

| Corrosion Resistance: | 96 Hours Salt Spray Test (ATSM B-117) |

| Outlet Check Valve: | None |

The system is designed to clean the 22gal tank on Wind Dragon in an hour. The plan is to power on the system every time we plan to be on-board for over an hour. I hope to add a timer at a later point to automatically cycle the fuel everyday.

Below are photos and notes of the installed system:

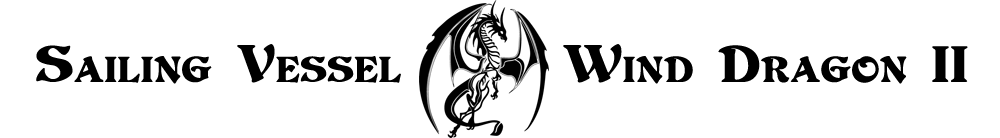

I mounted the parts on starboard attached to the frame that I installed our holding tank on.

In the photo below you can see the 10″ sediment filter, vacuum guage, and ball valves. You can also see the 12V landscape light I installed, a fluid transfer pump I use to move fuel from portable tanks to the main fuel tank, and pull switches that supply 12V power to all 3.

The photo below shows the Racor fuel/water separator and the Walbro fuel pump.

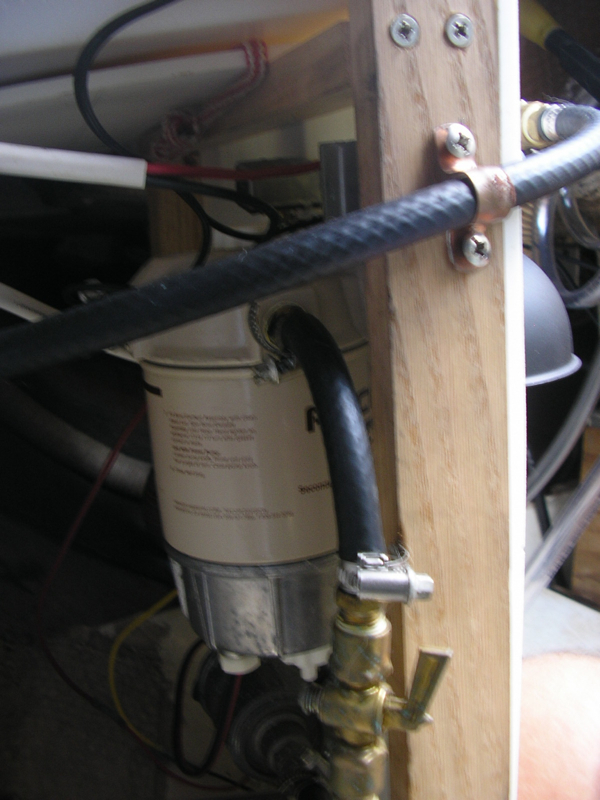

In the photo below shows wire and backside of switch, also the ball valve between the Racor and Walbro.

Below is a better photo of the 3 pull switches (Fuel polisher, fuel transfer pump, and light) the one pulled out is for the polisher

Below is a close up photo of the Fuel transfer pump (and the hold down strap for the sediment filter)

Below you can see the fuel line after it leaves the walbro pump. The upper ball valve (shown in the closed position) is one of the valves (shown in red on the diagram) that changes the flow of clean pressurized fuel from going back to the tank and into the engine. By-passing the main Racor in case it clogs up or the main fuel pump goes out.

Below you can see where the “Fuel by-pass” taps into the main fuel line after the main racor filter.

Below you can see the lines to and from the fuel tank. The one to the left is where the clean fuel goes back into the tank. This valve is shown in red on the diagram, is turned to the closed position to make the clean fuel by-pass the tank and go to the engine instead. The one to the right is where the fuel is pulled from the tank to be cleaned.